| ▲ Mechanical |

My parents bought this for me as a kit for my birthday. The kit comes with the bare castings and stock materials. You've got to machine all the components to make the engine. It took about 1 month to complete. Check out Stuart Turner's site at http://www.stuartmodels.com/.

Here's some pictures of the construction. They aren't in any particular order!

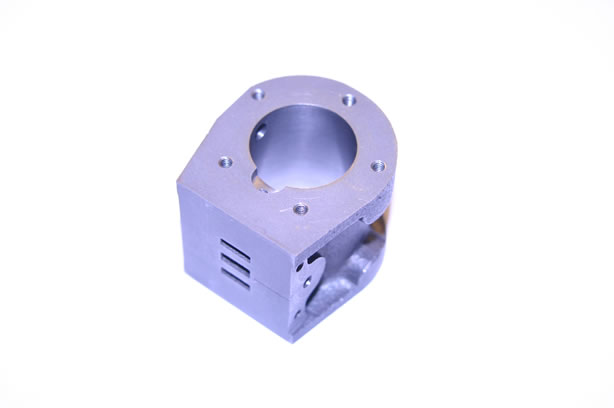

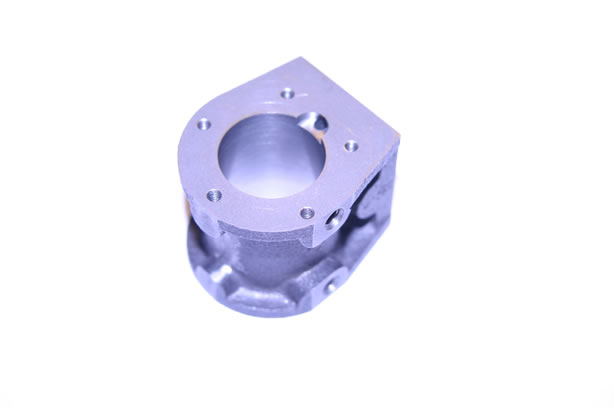

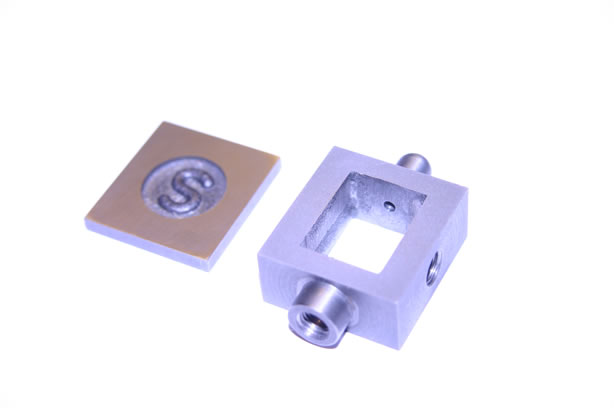

View of the cylinder showing the slide valve ports and the steam way recesses.

Another view of the cylinder

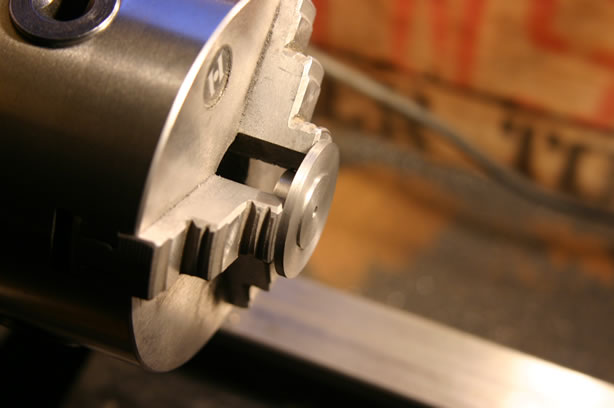

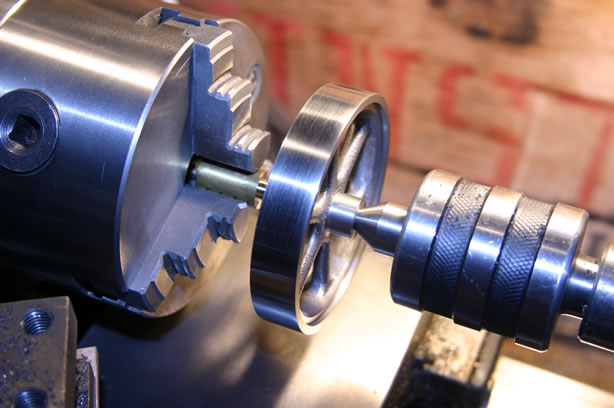

The bottom cylinder cover being turned down in the lathe. The piston rod slides in this and the gland nut screws into the opposite side.

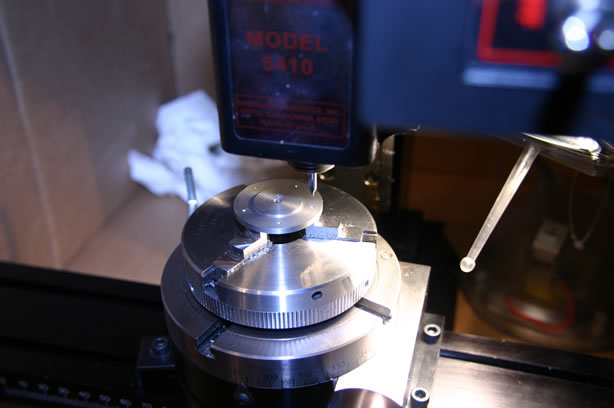

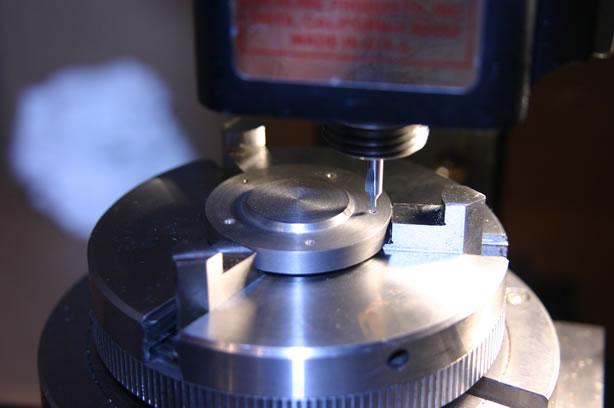

Drilling the bolt holes in the bottom cylinder cover using the rotary table in the milling machine.

Drilling bolt holes in the top cylinder cover.

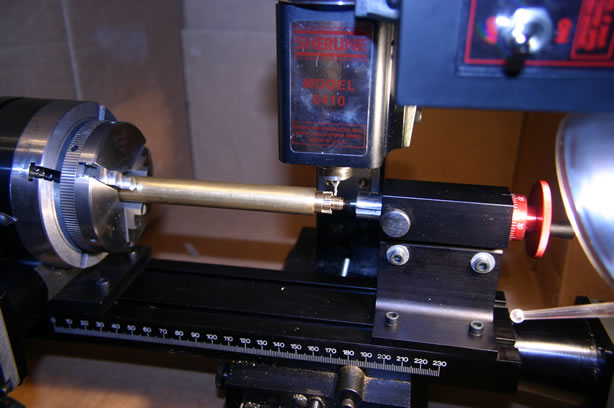

The bearings are made from a specially shaped extrusion of brass stock. The entire piece of brass is drilled and reamed in the lathed. The two bearings are then cut from it.

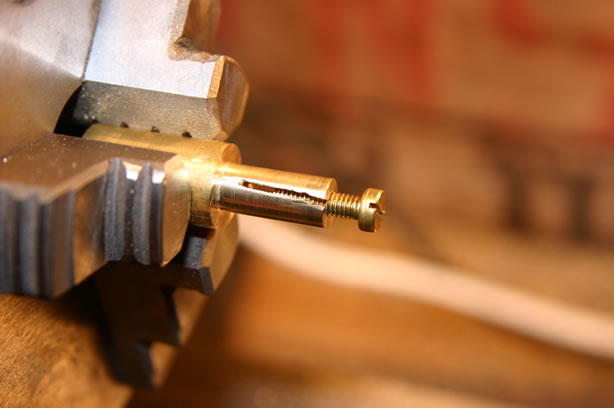

To turn down the ends of the bearings, I made a little expanding mandrel in the lathe.

The finished bearings with oil cups.

Using the mill to mill recesses for the bearings in the soleplate. I wrote a G-code program that moved the endmill in the X-Z plane to cut a semicircle. I then finished it off with files.

I discovered that the undersides of the bearings (where they are bolted to the soleplate) were not in line, so I had to mill them flat. I used the rotary table in the mill mounted so its axis was horizontal. I used the expanding mandrel to hold the bearings to machine them.

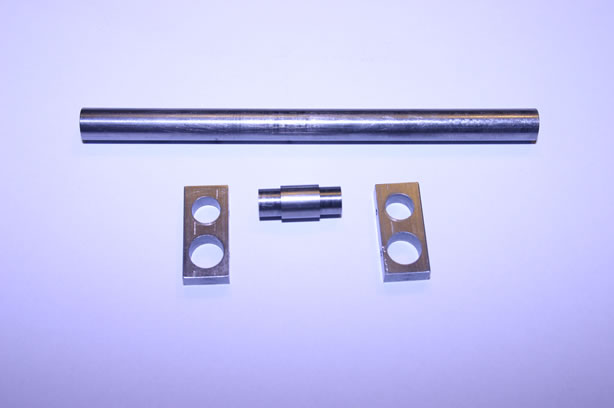

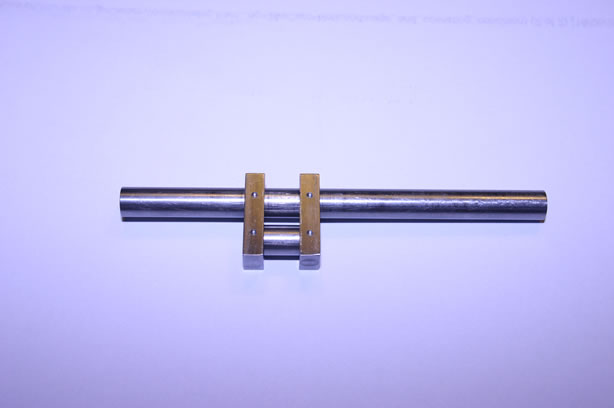

The various parts of the crankshaft; crankpin, webs and crankshaft.

Assembled. Once pinned (I used 2mm dia. roll pins), the part of the crankshaft between the webs will be cut out.

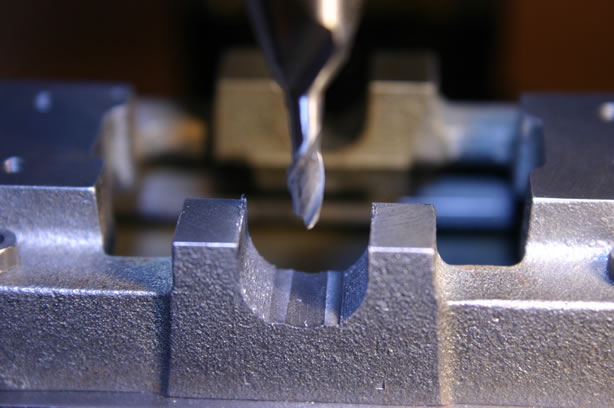

This was milling the slot for the crosshead in the end of the conrod.

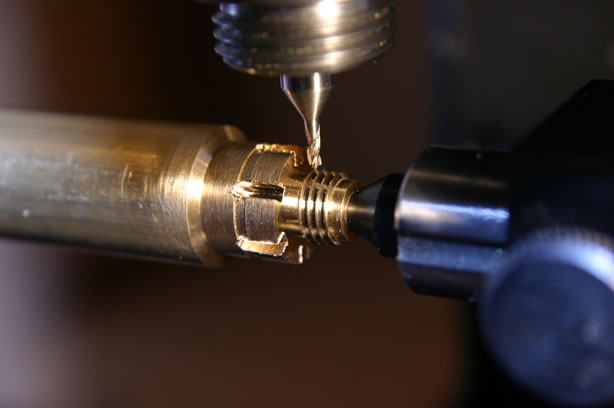

Milling the slots in the gland nut so it can be tightened with a screwdriver.

The rough casting.

Finished.

Valve rod gland nut.

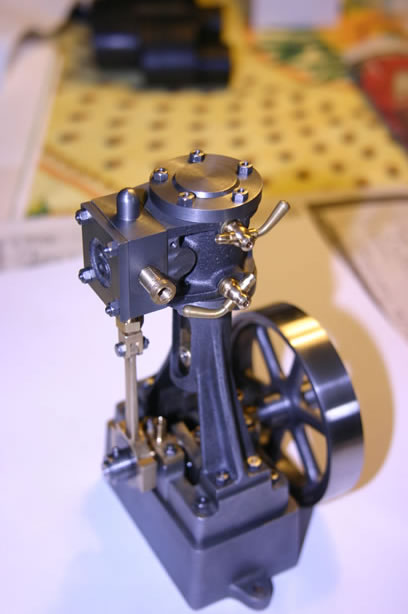

Here's the finished engine!

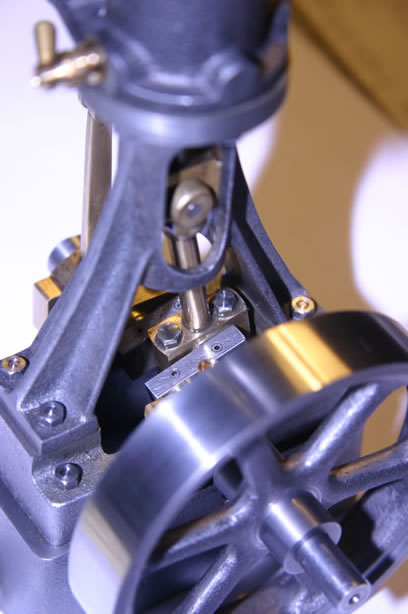

Closeup of the eccentric.

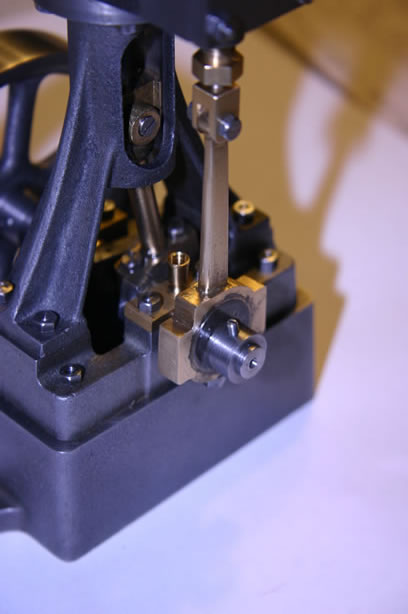

Closeup of the conrod and crosshead.

Sitting on top of the stove beside two engines my granddad made.

| ▲ Mechanical |